QAD Inc. (NASDAQ: QADA) (NASDAQ: QADB), a leading provider of flexible, cloud-based enterprise software and services for global manufacturing companies, held its QAD Tomorrow global thought stream, helping manufacturers identify supplier management challenges and providing best practices for optimizing supply chains for efficiency, agility, and resilience. QAD also announced the availability of the Integrated Supplier Management Diagnostic Tool that can help manufacturers quickly understand the levers that lead to better supply chain outcomes.

“Supply networks and supplier relationships are complex but increasingly critical to global manufacturing success. Customer demands change, shortages occur and sometimes, ships get stuck in the Suez Canal, causing a ripple effect through an already fragile supply chain,” said QAD CEO Anton Chilton. “When something in your ecosystem changes or suppliers experience a failure of any kind, your company needs to adapt fast. If you have a reliable flow of real-time demand and supply data during disruption events, you can quickly communicate adjustments with suppliers and your customers and can recover. Success, and even survival, of your business requires that your supplier network maximizes efficiency today and also has the agility to handle tomorrow’s disruptions.”

QAD Tomorrow streamed globally on May 19. Participants heard from QAD CEO Anton Chilton and CMO Carter Lloyds as well as QAD customers and industry experts discussing common supplier management challenges and outlining best practices for overcoming them. One can watch a recording of QAD Tomorrow by following this link. To access the Integrated Supplier Management Diagnostic Tool, follow this link.

“It was great to see registrations from South Asia countries up to 300 people,” said QAD Managing Director-South Asia, Jan Biezepol. “With disruption affecting manufacturing supply chains worldwide, smart managers have begun to give their relationships with their suppliers the attention they deserve and QAD can provide the tools to help them prepare for change. Many manufacturing companies that attended this thought stream illustrate the importance that management is now giving to cultivating and maintaining relationships with their suppliers.

Integrated Supplier Management

While Tomorrow 2020 introduced QAD’s vision for an Adaptive Manufacturing Enterprise, this year’s thought stream focused on one of the five crucial capabilities of an Adaptive Manufacturing Enterprise – Integrated Supplier Management – which helps manufacturers rapidly respond to supply disruptions and reduce supply chain risk. Integrated Supplier Management creates value for manufacturers by improving supplier collaboration, enabling optimal sourcing and deploying digital source-to-contract solutions. QAD offers a number of solutions, including, QAD Supplier Management, QAD Sourcing and QAD Supplier Portal, that facilitate real-time communication between manufacturers and suppliers while also eliminating manually intensive processes.

The Integrated Supplier Management Diagnostic Tool

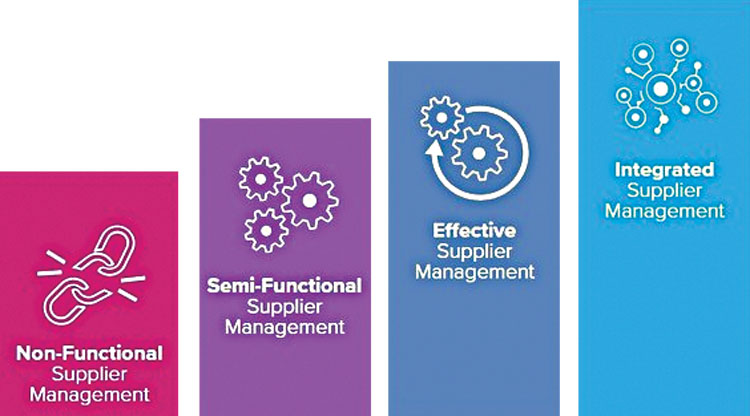

QAD Tomorrow also debuted the Integrated Supplier Management Diagnostic Tool designed to help manufacturing companies measure the state of their current supplier relationships and identify ways to quickly optimize supply chain efficiency, agility and risk. The 12-question assessment helps customers understand the levers that lead to better supply chain outcomes in the areas of delivery, costs, quality, sustainability and continuity, and prioritize projects with the highest, most rapid returns. The results of the Integrated Supplier Management Diagnostic Tool place manufacturers’ supplier management capabilities in one of four categories in the Integrated Supplier Management Maturity Model, which can help manufacturing companies begin to answer the following questions:

Are the company’s suppliers ready to respond quickly to and effectively deal with disruption?How does one’s company compare to an Adaptive Manufacturing Enterprise with Integrated Supplier Management?What can a company do to enhance supplier relationships to maximize supply chain performance?About QAD – Enabling the Adaptive Manufacturing Enterprise

QAD Inc. (NASDAQ: QADA) (NASDAQ: QADB), is a leading provider of adaptive, cloud-based enterprise software and services for global manufacturing companies. Global manufacturers face ever-increasing disruption caused by technology-driven innovation and changing consumer preferences. In order to survive and thrive, manufacturers must be able to innovate and change business models at unprecedented rates of speed. QAD calls these companies Adaptive Manufacturing Enterprises. QAD solutions help customers in the automotive, life sciences, consumer products, food and beverage, high tech and industrial manufacturing industries rapidly adapt to change and innovate for competitive advantage. Founded in 1979 and headquartered in Santa Barbara, California, QAD has 30 offices globally. Over 2,000 manufacturing companies have deployed QAD solutions, including enterprise resource planning (ERP), digital supply chain planning (DSCP), global trade and transportation execution (GTTE), quality management system (QMS) and strategic sourcing and supplier management, to become an Adaptive Manufacturing Enterprise. To learn more, visit www.qad.com or call +1-805-566-6100. Find us on Twitter, LinkedIn, Facebook, Instagram and Pinterest. “QAD” is a registered trademark of QAD Inc. All other products or company names herein may be trademarks of their respective owners.